Manage and control your warehouse with

WMS – Warehouse Management System

Trizeta offers an intuitive, efficient and customizable solution for complete warehouse management. The system is able to optimize the management of warehouse processes, from the arrival to the departure of the goods, passing through the inventory and the verification of the same.

What can ADeWMS do for you?

Based on a cloud platform, ADeWMS meets the needs of companies wishing to make an overall and significant improvement in warehouse management.

As a result, there will be errors reduction during product management operations as well as more streamlined and faster working method.

In addition, the integration with the ERP enables the import of all product data to be managed in the warehouse and the exchange of documents for goods handling.

Warehouse movement management with details

Automatic loading and unloading from arrivals and shipments

Customized alerts on stocks and unusual movements

Managing an order in several stages

Stock movement control

E-commerce integration

Real-time stock verification

Configurable labels in the control and labelling phase

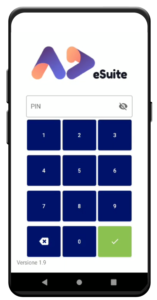

Associated Android handheld

ADeWMS associates an Android PDA with each warehouse worker so that each activity can be tracked and associated to its author thanks to the connected PIN.

Through this tool it is possible to automatically read the labels attached to the goods using bar or QR codes.

In addition to the Wi-Fi connection, the handheld can also access the network via a data SIM card, thus avoiding the need to invest in WiFi technology in warehouses.

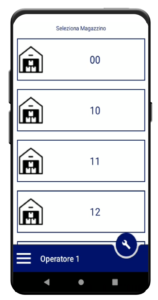

Warehouses list

The list of all the physical warehouses located in various units is displayed on the screen.

Once you have selected the warehouse where you want to work, you will have three types of document to work with (all with configurable parameters):

- sales

- purchases

- generic movements

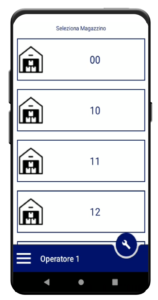

Warehouses list

The list of all the physical warehouses located in various units is displayed on the screen.

Once you have selected the warehouse where you want to work, you will have three types of document to work with (all with configurable parameters):

- sales

- purchases

- generic movements

Product features

For each product, the following information is shown:

- quantity available

- quantity picked up

- lot number/serial number

ADeWMS visually displays operations status:

- green (withdrawal operation is complete)

- yellow (withdrawal is to be completed)

- red (no goods in stock)

Following each change, the system will automatically recalculate the data and notify the movement of the goods.

Viewing orders from management

The order data and the status of the products in the warehouse are displayed in parallel by the management system in a document containing all the purchase orders and their details.

ADeWMS checks at any time how many goods are present and available.

Once the “inventory order” document has been created, all the orders counted by the operator will be taken from the office and a comparison will be made to detect any errors.

The inventory will confirm: item, position, quantity.

Product movements

The transaction table of a product contains various aspects, including the type of movement (parameterizable).

For example: product, quantity, lot, location, date, time and author the date, time and author of the transaction.